The Story of 'The Angels'

Where does all this information come from

Why were they called 'The Aycliffe Angels'?

What did the Factory manufacture?

Plans and Photos of the Factory (1940s)

TIMELINE of the Factory & Workers

Winston Churchill visits the Aycliffe Factory (1942)

Mrs Dillon - Senior ROF worker who received a medal

Honour at last, thanks to The Northern Echo

The Aycliffe Angels 2000-2020

Extremely dangerous work...

Workers' Houses and Accommodation

350 Houses on Secret Estate in Darlington

Photo Gallery 1 - (Admin Staff)

Photo Gallery 2 - (Production Staff)

Photo Gallery 3 - (Individual Angels)

Photo Gallery 4 - (ROF site in 1945)

Photo Gallery 5 - (ROF Fire Brigade)

Documents and Certificates etc...

What's left of Aycliffe ROF?

Surviving ROF buildings...

Links for History of The Aycliffe Angels

|

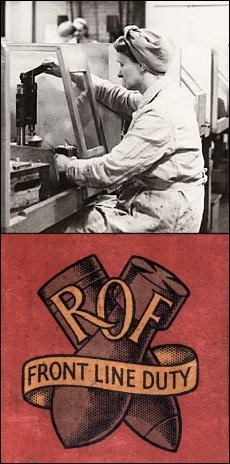

What did the Factory manufacture?

| The Aycliffe factory, ROF 59, was mainly a filling and assembly plant, putting powder into shells and bullets, assembling detonators and fuses.

Many of the component parts were manufactured elswhere in the UK and shipped to Aycliffe by rail.

Some of the ammunition casings were manufactured at another nearby ROF at Spennymoor, County Durham.

The Spennymoor ammunition was then filled at ROF Aycliffe. Spennymoor is known to have produced .303 cartridges in:

• Ball Mk 7 and 8Z

• Blank L Mk 5

• Incendiary B Mk 6, B Mk 6Z, B Mk 7 and B Mk 7Z

According to a book published in the late 1940s by HMSO, written by Ian Hay, detailing the history of the Wartime ROFs, Aycliffe produced some 700,000,000 (700

million!) bullets during its period of operation.

|

|

Highly Dangerous work!

The work was extremely repetitive, fragmented and boring, but high levels of companionship existed amongst the women as they risked their lives on a daily basis filling the bombs and bullets.

Many of the women started work at 18, not having experienced factory work before, but the average age at the factory was 34. Over 1,000 of the 17,000 workers were aged over 50.

Workers were supposed to be under the age of 50 to work at the factory, but many lied about their age and a Mrs. Dillon who claimed she was 49 was later discovered to be 69 years old! She received a decoration from the King for her work.

|

Operational Royal Ordnance Factories at the End of 1942

| No. |

Factory Name |

Factory Location |

Classification |

| 1 |

Woolwich |

London |

Engineering/Filling |

| 2 |

Enfield |

Middlesex |

Engineering |

| 3 |

Birtley |

Co. Durham |

Engineering |

| 4 |

Blackburn |

Lancs. |

Engineering |

| 5 |

Cardiff |

Glam. |

Engineering |

| 6 |

Cardonald |

Glasgow |

Engineering |

| 7 |

Dalmuir |

Dumbartonshire |

Engineering |

| 8 |

Fazakerley |

Liverpool |

Engineering |

| 9 |

Leeds |

Yorkshire |

Engineering |

| 10 |

Hooton |

Cheshire |

Engineering |

| 11 |

Newport |

Monmouthshire |

Engineering |

| 12 |

Radcliffe |

Lancs. |

Engineering |

| 13 |

Radway Green |

Cheshire |

Small Arms Ammunition |

| 14 |

Maltby |

Rotherham |

Engineering |

| 15 |

Wigan |

Cheshire |

Engineering |

| 16 |

Patricroft |

Manchester |

Engineering |

| 17 |

Ellesmere Port |

Cheshire |

Engineering |

| 18 |

Hayes |

Middlesex |

Engineering |

| 19 |

Poole |

Dorset |

Engineering |

| 20 |

Blackpole |

Worcestershire |

Small Arms Ammunition |

| 21 |

Spennymoor |

County Durham |

Small Arms Ammunition |

| 22 |

Steeton |

Yorkshire |

Small Arms Ammunition |

| 23 |

Nottingham |

Notts. |

Engineering |

| 24 |

Theale |

Berkshire |

Engineering |

| 25 |

Hirwaun |

Glamorgan |

Engineering |

| 31 |

Waltham Abbey |

Essex |

Explosive |

| 32 |

Bishopton |

Renfrewshire |

Explosive |

| 33 |

Irvine |

Ayrshire |

Explosive |

| 34 |

Pembrey |

Camarthenshire |

Explosive |

| 35 |

Wrexham |

Denbighshire |

Explosive |

| 36 |

Drigg |

Cumberland |

Explosive |

| 37 |

Bridgwater |

Somerset |

Explosive |

| 38 |

Ranskill |

Notts. |

Explosive |

| 51 |

Hereford |

Herefordshire |

Filling |

| 52 |

Chorley |

Lancs. |

Filling |

| 53 |

Bridgend |

Glamorgan |

Filling |

| 54 |

Glascoed |

Usk, Monmouth |

Filling |

| 55 |

Swynnerton |

Staff. |

Filling |

| 56 |

Risley |

Lancs. |

Filling |

| 57 |

Kirkby |

Liverpool |

Filling |

| 58 |

Thorp Arch |

Yorkshire |

Filling |

| 59 |

Aycliffe |

Co. Durham |

Filling |

| 60 |

Rearsby |

Leicester |

Filling |

| 61 |

Burghfield |

Reading |

Filling |

| 62 |

Healey Hall |

Rochdale |

Filling |

| 63 |

Ruddington |

Notts. |

Filling |

| 64 |

Walsall |

Staffs. |

Filling |

| 65 |

Elstow |

Bedford |

Filling |

| 66 |

Featherstone |

Wolverhampton |

Filling |

Types of Royal Ordnance Factories (ROFs)

1. Engineering - This type of factory produced bomb and shell casings and other metal-based components for all types of munitions.

2. Small Arms Ammunition - This type of factory was, in essence, an Engineering factory which specialised in the production of small arms shell casings.

3. Explosive - This type of factory produced the explosives for all types of munitions - cordite etc.

4. Filling - This type of factory took all the component parts and made the finished product. They filled bombs and bullets with the high explosives. The most dangerous of all the types of ROF!

Please click the link below to download a MS Word copy of the above list of Wartime ROFs.

Many thanks to Glen Chappelle from the ROF Heritage Centre at Glascoed for providing the list of Wartime ROFs.

|

|